Tetrahydrofuran (THF) is widely used across pharmaceutical, polymer, and fine chemical industries in India and the USA due to its solvent properties. However, THF drying efficiently to meet stringent moisture limits presents ongoing challenges. Traditional drying methods are energy-intensive and involve lengthy process times, while membrane-based approaches such as Pervaporation and Vapor Permeation offer innovative alternatives. This article compares these methods on key operational and economic parameters.

Traditional THF Drying Methods

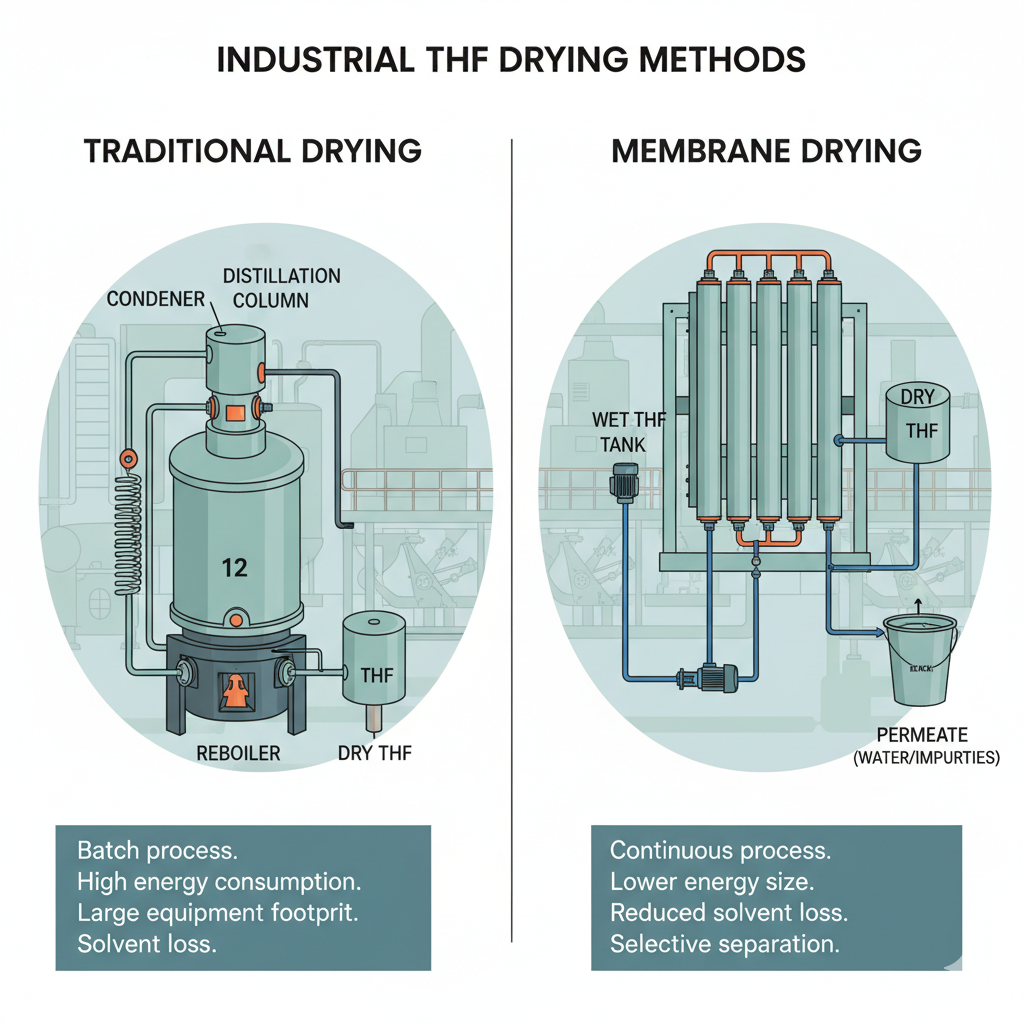

Distillation and Adsorption Techniques

The most common industrial method involves distillation, frequently with molecular sieves or sodium-based drying agents. Although reliable, these processes often demand high temperatures and extended cycle times to reach low moisture specifications. Additionally, they generate significant waste and energy consumption.

-

Distillation requires considerable heating, increasing operational costs.

-

Molecular sieves need regular regeneration and replacement, adding maintenance complexity.

-

Sodium or lithium aluminum hydride drying involves handling hazardous materials.

Operational Drawbacks and Environmental Impact

Besides energy consumption, traditional processes produce chemical waste streams and entail safety risks. Disposal of spent sieves and reactive desiccants must comply with environmental regulations, which heighten operational burdens. In India and the US, reducing such waste aligns with tightening sustainability mandates.

Membrane-Based THF Drying Technologies

Pervaporation and Vapor Permeation Advantages

Membrane technologies provide selective water removal from THF vapor or liquid, operating at lower temperatures and cutting energy use. Pervaporation membranes allow water molecules to pass through while retaining THF, reducing drying times and preserving solvent integrity. Vapor Permeation similarly separates vapors through membranes, enabling continuous drying with minimal thermal stress.

-

Operate at reduced temperatures, limiting solvent degradation.

-

Achieve high-purity THF with water content below 100 ppm.

-

Lower energy footprint compared to distillation, accelerating ROI.

Use of Zeolite Membranes for Enhanced Performance

Zeolite Membranes, with crystalline pore structures, deliver superior selectivity and chemical resistance. They are especially effective for continuous industrial drying applications. The integration of zeolite membrane systems improves throughput and reliability while reducing downtime for maintenance.

Key Comparison: Traditional vs. Membrane Drying

| Aspect | Traditional Drying | Membrane Drying (Pervaporation/Vapor Permeation) |

|---|---|---|

| Energy Consumption | High due to heating demands | Lower, operating at moderate temperatures |

| Process Time | Long batch cycles | Continuous processing possible |

| Purity Achieved | Moisture levels typically > 200 ppm | Moisture < 100 ppm achievable |

| Environmental Impact | Waste generation, hazardous materials | Minimal waste, safer operation |

| Maintenance | Frequent sieve regeneration, chemical handling | Membrane cleaning, less chemical waste |

| Initial Investment | Moderate to high | Higher capital but faster payback due to lower OPEX |

Practical Considerations for Industrial Deployment

-

Conduct feedwater and solvent characterization to match drying technology.

-

Assess integration potential with existing distillation or solvent recovery units.

-

Factor in regulatory compliance regarding emissions and waste disposal.

-

Monitor membrane lifespan and cleaning schedules to maintain performance.

Key Points

-

Traditional THF drying is established but energy and maintenance intensive.

-

Membrane drying methods like Pervaporation and Vapor Permeation offer efficiency and environmental benefits.

-

Zeolite membranes push the envelope of selectivity and durability for industrial THF drying.

-

Choosing the right drying technology depends on plant scale, purity targets, and sustainability goals.

Conclusion

For chemical manufacturers in India and the USA dealing with acetone drying, DMF drying, IPA drying, and especially THF drying, shifting from legacy distillation to membrane separation technologies unlocks operational and economic advantages. I3 Nanotec delivers cutting-edge solutions involving Zeolite Membrane, Pervaporation, and Vapor Permeation technologies that enable reliable, energy-efficient, and environmentally conscious solvent drying. Collaborating with I3 Nanotec facilitates overcoming industrial drying bottlenecks while driving sustainable growth.