Chemical purification is fundamental in industries ranging from pharmaceuticals to fine chemicals. Traditional methods—like distillation—have long served the field, but rising demand for cleaner, more energy-effective solutions has driven innovation. In this shifting landscape, ZEOLITE MEMBRANE technology is quietly becoming a go-to solution for the future.

What Sets ZEOLITE MEMBRANE Apart?

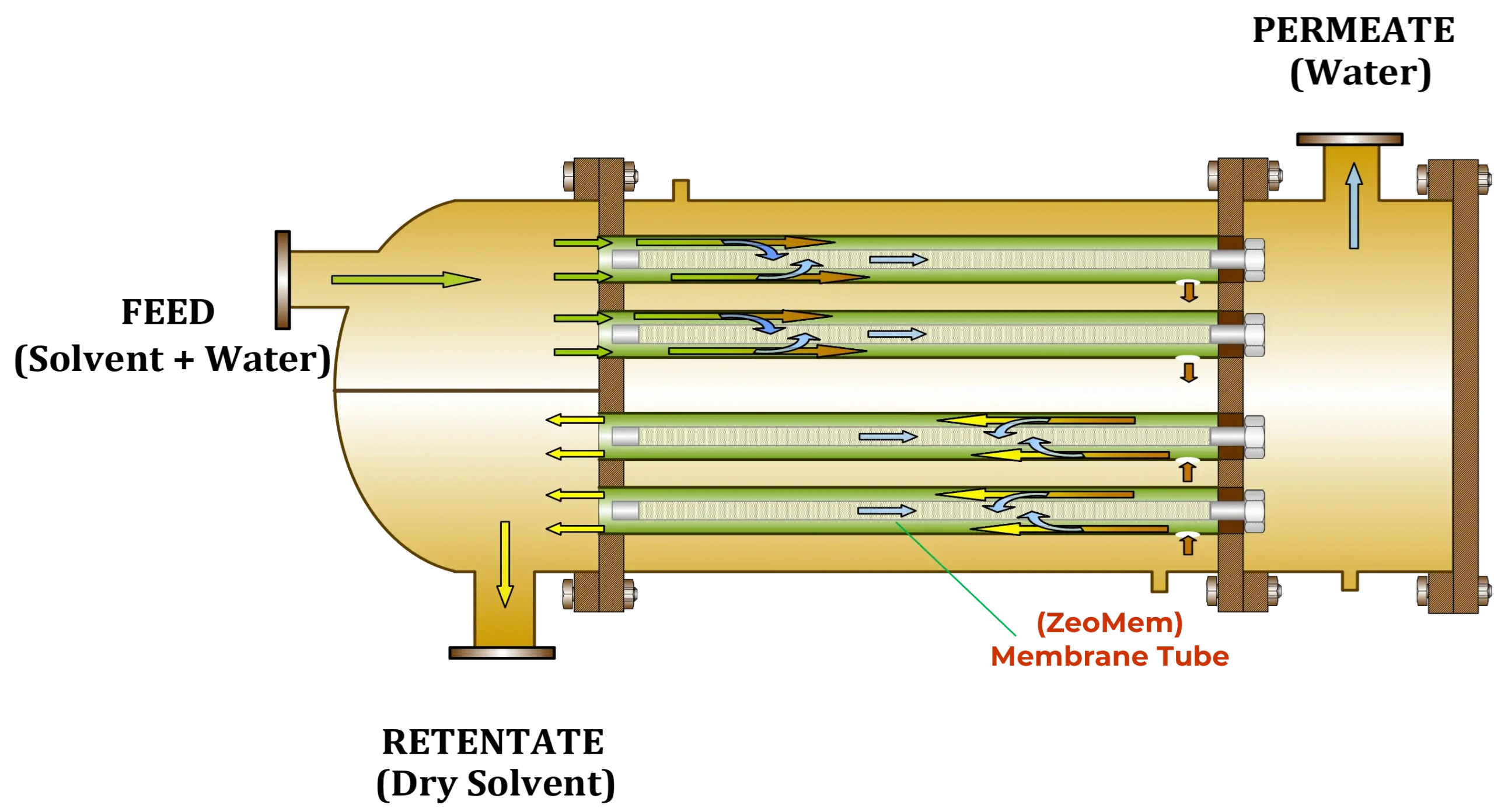

ZEOLITE MEMBRANE offers distinct advantages for separating and purifying chemical mixtures. Unlike many other materials, the zeolite’s tightly-controlled pores act like tiny molecular sieves, letting only select molecules pass through. As a result, ZEOLITE MEMBRANE can achieve exceptional selectivity for both vapor and liquid phase processing.

Key Benefits of ZEOLITE MEMBRANE

-

Withstands high temperatures and harsh chemicals without losing structure.

-

Delivers reliable results in processes where traditional polymer membranes struggle.

-

Enables both Vapor Permeation and Pervaporation, offering flexibility for a variety of jobs.

Vapor Permeation and Pervaporation: The New Workhorses

For challenging tasks such as Methanol drying or ethanol dehydration, ZEOLITE MEMBRANE paired with Vapor Permeation or Pervaporation leads to remarkable gains. These techniques work by passing a mixture through the membrane—either as vapor or liquid—so water and other undesired components are removed. The separation hinges on both size exclusion and chemical affinity, with zeolite’s structure favoring the passage of certain molecules.

How It Works

-

Vapor Permeation: The feed enters as a vapor. Water vapor migrates through the membrane, leaving behind purer methanol or ethanol.

-

Pervaporation: Works with liquid-phase feeds. Water is extracted directly, making it invaluable in Methanol drying and solvent recovery.

Membrane Reactor: Merging Separation and Reaction

A Membrane Reactor combines reaction and separation in a single process, using ZEOLITE MEMBRANE to draw off water or by-products as a reaction proceeds. This integration not only increases product purity, but can even shift chemical equilibria, helping boost yields and process flow.

Types of Applications

-

Peptide purification

-

Ethanol and Methanol drying

-

Speciality chemical processing

These applications benefit from the ability to remove water or unwanted by-products as soon as they are formed, streamlining purification.

Versatile Use Cases for Industry

ZEOLITE MEMBRANE’s appeal is not just academic. In practice, leading industries adopt this technology for efficiency, reliability, and reduced energy demand.

-

Lower utility costs compared to high-heat distillation.

-

Fewer secondary by-products generated.

-

Found in pilot and commercial-scale operations worldwide.

Sustainability and Future Trends

Forward-thinking companies are under pressure to reduce emissions, save energy, and get more from existing resources. ZEOLITE MEMBRANE systems—especially when combined with Pervaporation or Vapor Permeation—present a proven path to sustainable chemical purification.

-

Less energy required per unit of pure product

-

Reuse and recovery of valuable solvents, protecting both the environment and business margins

Maintaining Top Performance

ZEOLITE MEMBRANE systems are designed for long lifespans, even under intense operating conditions. Routine monitoring and periodic cleaning keep the system operating steadily, with service teams available for support if technical questions arise.

Considerations for Implementation

Before integrating this technology, evaluate:

-

Desired purity levels

-

Feed mixture composition

-

Energy and operational requirements

Working with knowledgeable experts eases the transition and helps optimize the set-up for individual needs.

Conclusion

ZEOLITE MEMBRANE is quietly building its reputation as a cornerstone for the future of chemical purification. Whether for Methanol drying, solvent recovery, or advanced Membrane Reactor applications, these systems are positioned to meet the needs of industry today and tomorrow. As challenges evolve, ZEOLITE MEMBRANE stands ready—combining proven chemistry with smart design.

Those investing in this solution gain not just efficiency, but the confidence of having a separation tool calibrated for tomorrow’s demands.